From farm to table, literally

By Joseph L. Garcia, Reporter

ROOTS run deep in a family-owned tree plantation in Pangasinan. The plantation, owned by the Sebastian family, produces wood furniture straight from the trees planted on their own land, resulting in a product that is truly from farm to (a) table.

“The main advantage that we have is our farm-to-table — literally a table [chuckles] — setup; from planting to harvesting to production, everything is done in our own backyard. This eliminates a lot of the in-between costs that most production facilities incur,” said SustainablyMade Chief Operating Officer and Chief Designer Marco Sebastian in an interview with BusinessWorld.

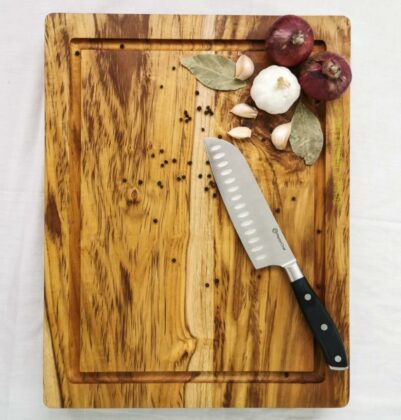

SustainablyMade is the brand under which the family sells the furniture by its company, MARSSE Tropical Timber. Each piece is crafted, sanded, and finished by local farm workers who have been given woodworking skills training. These result in furniture, and kitchen and home accessories made with expressive wood grain that are sold in some of Manila’s most well-known trade fairs and stores (such as Manila FAME, ArteFino, and Rustan’s).

“The manufacturing processes for our standard items are broken down into simple steps that any person with a few weeks of training will be able to do. This has worked for us for the longest time since labor in our area consisted mostly of rice farmers,” Mr. Sebastian said about the training the artisans have received. “In the beginning, what we tried to do with our company is to simplify mostly tedious and complicated woodworking processes to allow our workers to output high-quality products with minimal skill and equipment.”

And as the company grew, so did the workers who have been with SustainablyMade since the beginning. “They have shadowed myself and my brother as our apprentices and are now highly skilled and specialized artisans themselves.”

EVERGREEN

While sustainability has become a marketing buzzword for products that purport to help the planet, Mr. Sebastian listed practices at the tree plantation that prove their point. They actively grow saplings, along with the natural passive growth of wildlings, and they harvest on a “first-in, first-out” basis ensuring the long-term sustainability of the wood resource. They do not keep a log pile (or a stock of fallen trees) to maximize the environmental benefits of a standing tree.

They only harvest when there is a job order, and they employ a “No Wood Wasted” policy where the entire fallen tree is used. The leaves are used as fertilizer for their seedlings. The small branches are made as firewood; the roots are made as sustainable charcoal.

“The advantage is that [the No Wood Wasted Policy] forced us to be creative with our design and production processes. Every piece of wood, in the form of big timber slabs, branches, or small unevenly cut scraps, is still wood; it can be shaped, molded, joined, and worked into any product as long as creativity, budget, and practicality permits. This allows us to make the most use out of the raw materials that we have heavily invested in for the past 30 years.”

Mr. Sebastian extolled the benefits of having their own tree plantation, which has been in the possession of the family for about 30 years. “Waking up to fresh air and less noise every day!”

On a more serious note, he said: “We are assured of our raw materials for our woodworking business since we are not reliant on others for this supply. Knowing that our supply is readily available and that it is propagated in a responsible manner gives us peace of mind.”

The advantages of being family-owned are numerous. Chief among them is that compared to businesses on leased government land or concessions, SustainablyMade is not as affected by policy changes that come around every six years.

“You also have security of tenure on your land, no fear of being evicted with the change of administrations; this gives a long-gestating project, such as tree farming, the proper time it needs to fully realize its potential,” he said.

“As a family, we have control on the direction of our company,” added Mr. Sebastian. “Decisions are made easy since communication between us siblings is always open and we generally have the same vision and mission when it comes to what we want to happen…of course, we still need the help and expertise of people who are more knowledgeable than us in things such as marketing, export, and other things pertaining to the ‘selling’ part of the business.”

The plantation is currently growing 130,000 trees, by Mr. Sebastian’s estimate. Will this number grant their promises of sustainability? “We harvest roughly 200 to 400 trees a year, which is less than one percent of the tree farm’s population. Due to our small scale and limited resources, we use selective harvesting to supply our timber business. We typically harvest the largest trees from a given area to give the smaller trees equal opportunity to sunlight and nutrients; this maintains a mean growth throughout the farm. This system also allows us a three-to-five-year harvest rotation per lot area in the farm, keeping the farm in an evergreen state.”

WOOD WITH PEDIGREE

The tree farm — and thus, the furniture and accessories made from it — contains tropical hardwood trees, mainly Honduras mahogany and other species like gmelina and teak, molave, and kamagong.

Asked what it’s like to work with woods of such pedigree, Mr. Sebastian replied: “We have had some instances of working with native and endemic hardwoods from the Philippines. My general impression is that these woods are of high quality and character and are mostly a joy to work with. However, due to these woods being either protected species or in the endangered lists, permits and licensing of these woods make it difficult to be the main crops of tree farms — at least for this generation.”

“That is why most of the wood that we plant and that we use in our woodworking business are foreign trees that are considered farming species, such as mahogany and teak. Their quality as timber is world-renowned and they generally grow faster as compared to some local species. Farm species are easier to get permits for as long as you have complete documentation,” he said. “This is not to discredit native and endemic trees since they are also of world renown and of high quality. It is just that they are not as easy to propagate due to their long maturity rate and possible harvest turnovers. We do also plant these trees, but they are left for our conservation areas.”

At the same time, he points to the reputation of mahogany as an invasive species in the Philippines (his knowledge comes from his degree in Environmental Science): “We know that mahogany has a bad reputation as a tree in the Philippines; it is invasive to our natural forests, drains up water supply, debilitates local wildlife, and is a vehicular hazard when it’s seed pods fall. All of these are true. However, this is mostly due to the improper use and placement of these trees in reforestation endeavors. In a controlled agro-forestry environment, these trees flourish and even sustain wildlife as can be seen in our farm. This has in-fact, raised the water tables in our area and resulted in the manifestation of springs within the farm. Each tree species has its own purpose.”

THE PRICE OF SUSTAINABILITY

With the way the world is, “sustainability” as a label has become a bare minimum for brands. Mr. Sebastian discusses how they maintain their own values, and how that translates into value for the consumer.

“Personally, I think that ‘sustainability’ is a privileged concept. We are an example of that privilege; if not for our parents’ time, money, and effort we would not have this farm that we can live on and develop timber practices that are responsible and sustainable. Likewise, we spend a lot of time, money, and effort to maintain the sustainability aspect. We had the resources and the knowledge to start moving, that is why we were able to achieve sustainability in our tree farm,” he said. “I think that is what people need to realize, that true sustainability right now comes at a price. This is why most products that practice and encourage sustainability are usually on the more expensive side.”

SustainablyMade’s products come in a range of prices: some of them, such as their mobile phone stands, can cost up to P240, while a laptop table costs P4,500.

“With more companies shifting to a greener business — restaurants shifting from plastic to paper and car companies starting to heavily invest on the electric future — true environmental sustainability may not be far-off. Hopefully, sustainability and a greener/more sustainable lifestyle become more available and affordable to the general community.”

Suppose a more sustainable lifestyle does become more accessible to more people, Mr. Sebastian’s goals for the company aren’t too ambitious. It’s not to fill every home with a SustainablyMade cheeseboard (P500), extra-large teak butcher block (P8,000), or wine hat (P300).

“Our end goal is simply to get consumers to ask, ‘Where does your wood come from?’ If consumers become more conscious of the sources of the products that they buy, hopefully, manufacturers, small and large, can realign to be more environmentally sustainable and responsible with their practices.”

SustainablyMade products are available at www.sustainably-made.com, Rustan’s, Kultura, DTI-GoLokal!, HumanNature, CommonRoom, The Craft Central, and The Good Trade PH.